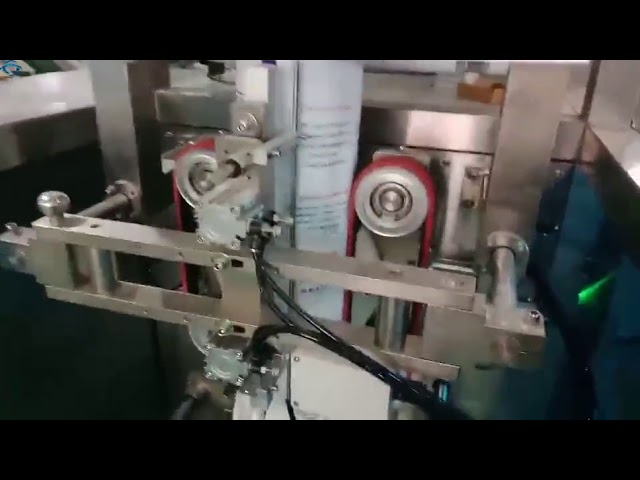

Iapack supplies machines for filling and sealing pre-shaped flat bags or standup pouches. The foundation of the machine is an intermitting, rotating carousel. Grips are attached to this carousel from which the pre-formed bags are hanging. The rotation of the carousel makes sure the bag passes different stations where a specific action takes place, such as opening the bag, filling it and sealing it.

Depending on the application (fresh, atmospheric or vacuum) or product (liquid, solid or powder), the product passes 8, 9 or 10 stations. The machines are also suitable for filling a combination of solid and liquid products, such as animal food, meals, preserved olives, etc.

Introduction to automatic pouch packing machines

Bag filling and sealing machines can be designed with an inline or rotary layout. For the purpose of today's article, we are diving deeper into the rotary layout. This design conserves plant floor space and is constructed with ergonomics top-of-mind, and thus is seeing more popularity than inline models.

Simplified, rotary automatic pouch packing machines grip a preformed pouch, fill it with product, and seal it, at speeds of up to 200 bags per minute. This process involves moving the bag in an intermittent rotary fashion to different 'stations' positioned in a circular layout. Each station performs a different packaging task. There are usually between 6 and 10 stations, with 8 being the most popular configuration. Automatic pouch filling machines can also be designed with a single lane, two lanes, or four lanes.

The Automatic Pouch Packaging Machines for powder and granules are judged for its precision on the long run and also its high speed and durability in all sorts of conditions. Our machines meet the highest of international standards when it comes to a quality output. We offer spices packing machine, automatic spices packing machine, detergent powder packing machine, tea packing machine, automatic packing machine, biscuit packing machine.

Pouch Packing Machine Show

We provide our clients with impeccable quality pouch packing machines that are developed using advanced technology. These resilient machines are structured to make different types of pouches and cater to the needs of various industries. Salient attributes of our pouch packing machines include total PLC control, highly automatic and compact, robust & modular design. The range can also be customized as per the specifications of our esteemed customers.

Streamline your operations and increase output by as much as 50 percent with our rotary premade pouch machines. Unlike our vertical form fill and seal machinery that utilizes roll stock film to create bags, our premade pouch packing machines offer something completely different. These innovative packaging machines fill and seal already premade custom pouches, so no rollstock is required. The end result – your packaged product looks modern, offers convenience, and differentiates itself from your competition.

Application

Rotary bag-given packing machine with different dosing (such as multihead weigher,auger filler,liquid filler etc.) can be suitable for the automatic packing for granular, powder, liquid, paste etc. Different kinds of product with the premade stand-up zipper pouch and so on.

Solid: Candy,peanut,green bean,pistachio,brown sugar,c ake, daily commodities, cooked food, pickles, puffed food etc.

Granule: Grain, granular drug, capsule, seed, condiment, granulated sugar, chicken essence, melon seeds, nuts etc.

Function And Characteristics

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

6)The packing materials loss low, what this machine is used the preformed bag pattern is prefect and has a high quality of the sealing part, this improved product specification.

7)Product or packing bag contact parts adopt stainless steel or other materials which accord with the food hygienic requirements, guarantee hygiene and security of the food.

How do Automatic Pouch Packing Machines Work?

Automatic Pouch Packing Machines are becoming increasingly popular today for their simplicity, ease-of-use, and the superior aesthetics of their finished product.

Whether you are new to packaging automation or are considering adding premade pouch packaging to your product lineup, you are probably interested in how these machines operate.

Today we are taking a step-by-step look at the processes involved in turning an empty premade pouch into a shelf-ready finished product.

Here is how the pouch packaging process works:

1. Bag Loading

Preformed pouches are loaded manually by an operator into the bag magazine in the front of the automatic pouch packing machine. The bags are conveyed to the machine by a bag feeding roller.

2. Bag Gripping

When a bag is detected by a proximity sensor, a vacuum bag loader picks up the pouch and transfers it to a set of grippers, which will hold the bag as it travels around the rotary unit to different 'stations'.

These grippers can continually support up to 10 kg on the best bag filling and sealing machine models.

3. Optional Printing/Embossing

If printing or embossing is desired, that equipment will be placed at this station. Pouch Packing Machine can utilize both thermal and inkjet printers. The printer can place desired date/lot codes on the pouches. The embossing option places raised date/lot codes into the bag seal.

4. Zipper or Bag Opening & Detection

If the bag has a zipper reclosure, a vacuum suction pad opens the lower part of the preformed pouch and opening jaws catch the top side of the bag. The opening jaws separate outward to open the top of the bag and the premade pouch is inflated by an air blower. If the bag does not have a zipper, the vacuum suction pads still open the bottom part of the pouch but only the air blower is engaged.

Two sensors are present at the bottom of the bag to detect its presence. If a bag is not detected, the filling and sealing stations will not engage. If a bag is present but not placed correctly, it will not be filled and sealed and instead stay on the rotary apparatus until the next cycle.

5. Bag Filling

Product is dropped down a bag funnel into the bag, usually by a multi-head scale. For powder products, an auger filler is used. In the case of liquid packing machines, product is pumped into the bag by a liquid filler with a nozzle. The filling apparatus is responsible for the correct measurement and release of discrete quantities of product to be dropped into each premade pouch.

6. Product Settling or Other Options

Sometimes loose contents need to settle to the bottom of the bag before sealing. This station gently shakes the premade pouch to achieve that.

Other options at this station include:

Second liquid seal. For liquid/water pouch filling machine configurations, this station can be used for a second liquid seal to ensure maximum seal integrity.

Second filling station. For products that include both solid and liquid components, a second filling station can be added here.

Load shelf. For heavy fills, a shelf can be added after filling to bear the load of the extra weight and take the stress off of the gripping arms.

7. Bag Sealing & Deflation

Remaining air is squeezed out of the bag by two deflator components before sealing occurs.

A hot seal bar closes on the upper part of the pouch. Using heat and pressure, the sealant layers of the premade pouch are bonded together to make a strong seam.

8. Cooling & Discharge

A cooling bar passes over the seal to strengthen and flatten it. The finished bag is then discharged into a receptacle or onto a conveyor and can be transported to downline equipment like check weighers, x-ray machines, case packing, or carton packing equipment.