Iapack designs and manufactures packaging machinery for sugar and other granular and powdery food products, such as sweeteners and fructose, in an ideal bar sachet format.

Iapack has been in the packaging business for many years, and it owes its success especially to its lengthy experience in the granular and powdery products packaging sector, thanks also to our specialization in the production of customized sachets.

In fact, Iapack manufactures a wide range of packaging machines for sugar and other powdered products; all our units are subjected to frequent tests and inspections, verifying improved performances so as to satisfy the specific needs of all our customers.

Iapack aims to offer innovative and versatile sugar packaging solutions that protect and preserve the inherent goodness of sugar, enhancing the brand value.

Sugar Packing Machine Show

Iapack’s machines and integrated packaging solutions help the manufacturers package various quantities of sugar up to 10kg in versatile pouch formats that are hygienic, leak-proof and convenient for storage. Apart from protecting the contents, these pouches help the manufacturer’s brand stand out on the retail shelf and also to compete in the international market.

Iapack’s sugar packaging machines are capable of functioning at a speed of 120 pouches per minute, accurately and with minimal wastage.

Sugar Packing Machine Features

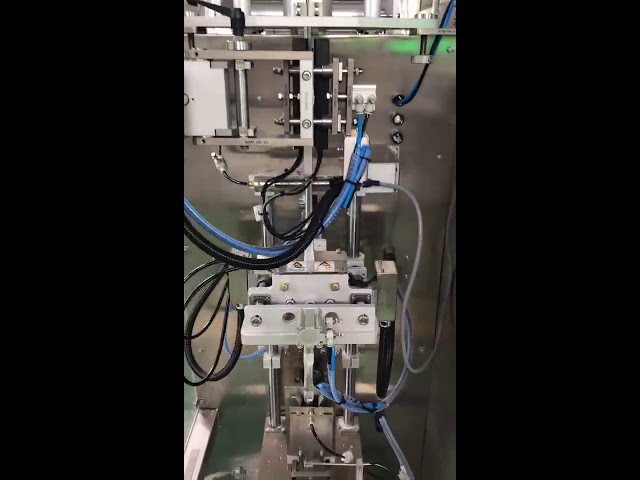

Easy to operate, adopt advanced PLC from Germany Siemens, mate with touch screen and electric control system, the man-machine interface is friendly.

Automatic checking function: no pouch or pouch open error, no fill, no seal. the bag can be used again, avoid wasting packing materials and raw materials.

Safety device: Machine stop at abnormal air pressure, heater disconnection alarm.

The width of the bags could be adjusted by electrical motor. Press the control-button could adjust the width of clip, easily operate, and save time.

The part where touch to the materials is made of stainlesss steel and according with the request of GMP.

Main Technical Parameters

| Working position | Six-working position |

| Bag material | Laminated film/PE/PP |

| Bag pattern | Stand-up with zipper & stand-up, spout, flat bag, |

| Max filling weight | 10-5000g |

| Filling accuracy | 0.5-1.5% |

| Bag size | W:100-200mm L:100-350mm (could be customized) |

| Speed | 10-60bags/min |

| Voltage | 380v 3phase 50/60hz |

| Total power | 5.5KW |

| Compress air | 0.6m³/min |

Sugar Packaging

Sugar is the main sweetening material that the modern world cannot give up. Thousands of tons of sugar are consumed on Earth every day. Well how much sugar is in front of the end user. Of course, with sugar packing machine. Sugar packaging machine is one of the most important machine groups in the packaging machinery sector.

Sugar Packaging Filling:

There are 2 kinds of machine type for sugar packaging:

1- Single Use Stickpack Sachet Format

With this machine you can automatically fill all kinds of special free flowing granules including white sugar, brown sugar, sweetener, cinnamon, salt, pepper, all spices, aromatic fruit drinks, granular coffee, free flowing powder and Silica Gel Pouches under sterile conditions. We build sugar sachet packing machine and stick sugar packaging machine for single use portion pack sugar. All our sugar packaging and filling machines are low cost and high quality, extremely compact, very fast (up to 15 lanes) and can handle to produce 750 pcs / min. Both our sugar stickpack machine and vertical form fill and seal machines are equipped with volumetric fillers.

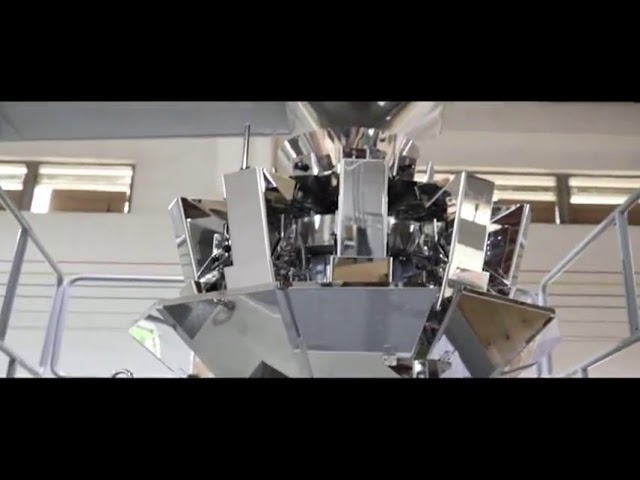

2- Vertical Packaging Machine for Big Bags

For 1 kg sugar filling machine vertical packaging machine is used and if you are looking sugar packaging equipment for powder packing machine and granule packing machine with auto feeding systems vertical sugar packaging machines are the best choice. 1kg Sugar Packing Machine is equipped with volumetric fillers. Up to 60 pcs/min speed, you can fill 3.600 kg per hour. In 10 hours shift you can package and fill 36 tons sugar with Iapack’s 1kg Sugar Packing Machine easily. Iapack is the best supplier and manufacturer of sugar filling machines in China. Not only granular white or brown sugar, but also powdered fine sugar can be packed with our vertical packing machines. But for non-free flowing powdered products we use auger dosing screw feeders.

Sugar Types:

Wondering how does Sugar packaging works? Not only that, Coconut, Palm, Granulated, Powdered, Icing and Raw Sugar packaging, all the above-mentioned types are packed in the same way as the White Sugar Packaging.

Types of Sugar Packaging Machine:

Stick Pack Machine for Free-Flowing Products (Sugar)

Iapack Sugar Stick Packing machine is used for granular free flowing products with weight range between 1 gr-20 gr. It’s commonly used for free-flowing foods or other kind of products such as sugar, salt, black better, granule coffee, Nescafe gold coffee, salt, and various kinds of granular products etc. The machine utilizes a single roll of heat-sealing film, or, in other words in the quantity of packaging lanes. A tubular sleeve is made of each strip, and after that fixed the long way; the even fixing unit frames the stick. Special variants can be provided on demand.

4-Side Sealed Sachet Packaging Machine for Granular Products

This fully automatic packaging machine that is designed to prepare a 4-side sealed sachet-type package to fill free flowing granular products like sugar, salt, and spices like free flow black pepper. Products that have self-flowability like sugar, three-in one coffee, salt, black pepper, energy drinks and other medical grained granules can be packaged through precise volumetric cups using this model. This machine can produce 160 pcs/min using with 4 channels. The machine is overseen totally electronically; dealing with activities are ensured by brushless servomotors, and a touch screen administrator interface takes into consideration high accuracy. Extraordinary variants can be provided on demand.

Sugar Packaging Process & Sealing:

The film is loosened up from the film reel, situated at the back part of the machine. The film loosening up process is finished by means of movement of the cross-seal jaws, situated at the front of the stick pack machine. If that the machine is outfitted with a date-stamping device, the film is fed around an enrollment roller. This registers the situation of the date stamp on the package in connection to the horizontal seal. The film is strung over a sensor that peruses eye checks and controls the situation of the even seal in connection to the imprinting on the film.

Next, the film is sustained through an arrangement of nip rollers. The nip rollers keep even pressure on the film to keep it at a consistent pressure, therefore keeping the arm in the best possible working position.

From the nip rollers, the film goes into the cutting area. Amid this progression simultaneously, the extensive move of packaging film is cut into strips dependent on what number of paths the stick pack machine has. These strips frame the reason for the individual stick packs.

From here, the cut film passes numerous shaping tubes (one for every lane). As the cut film peaks the shoulder (neckline) on each framing tube, it is folded around the tube, so the final product is a ‘STICK PACK’ or ‘SACHET PACK’ shape with the two external edges of the film covering one another.

Once the film stops moving, multiple vertical sealer bars (one for every path), which are hot, push ahead and reach the vertical cover on the film. The vertical seal bar squeezes itself against the shaping tube and makes the vertical seal.

After the product has been discharged into each stick pack, the knife pushes ahead and cuts the pack, or the horizontal seal is “indented” simply under the level seal jaw.

Completed stick packs drop into the outfeed chute which has a fold that opens and closes at foreordained interims, dropping the sacks either onto an outfeed conveyor or specifically into a repository. For a more controlled and situated release of stick packs, individual outfeed chutes can be optioned.